Until recently, AquaPack Robotics would build an autonomous underwater vehicle (AUV) named SeaWolf, repair and use it until it was ready to retire, and then scrap the old robot for parts to build a new one.

The student-led team, which is open to all NC State University students, participates every summer at the RoboSub competition. Over the school year, members repair and improve their current robot or build a new one, then test its abilities through a variety of tasks.

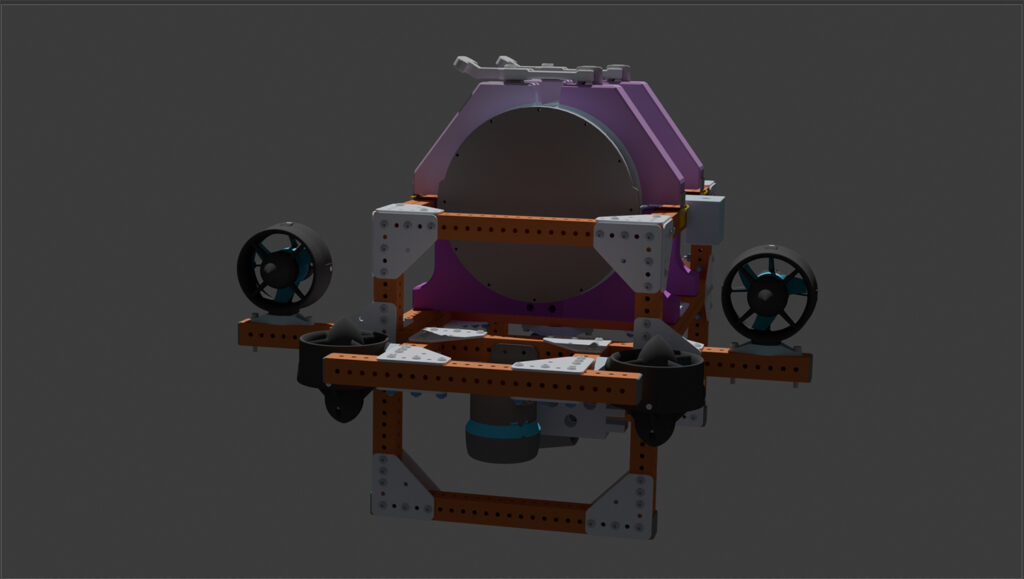

But over the last school year, the AquaPack team spent more than 70 percent of its time designing a new robot, SeaWolf 9, while updating and practicing with its current AUV, SeaWolf 8.

“That was one of the big things we wanted to change about the organization’s design cycles,” said Chris Mori, 2023-24 club president and Ph.D. student in electrical engineering. “That allows us to keep the old robot to teach people while also having a stable competition vehicle. Whereas the new robot, it really gives us a lot of flexibility and a lot more time to make good design decisions… And promoting that kind of design cycle is more akin to what you would face in the real world.”

Making the final

For this summer’s competition in Irvine, California, AquaPack will use SeaWolf 8. Next year, they want to compete with both SeaWolf 8 and SeaWolf 9, and then exclusively use SeaWolf 9 in 2026.

The team hopes to improve on its 2023 RoboSub results in San Diego, where despite low expectations — some team members weren’t sure they’d get the robot past the qualification test — they finished with a score 300 points higher than in 2022.

“We weren’t expecting that because we overhauled three systems: our acoustic system, our software system and our control board,” said Tajah Trapier, former club president and current Ph.D. student in materials science and engineering.

Since then, AquaPack has made even more changes to SeaWolf 8. Members revamped the passive sonar system, changed its coding framework from Java to a new, user-friendly language called Rust, implemented a new torpedo system and replaced some 3D-printed parts with metal parts.

This year, the team believes it can make the RoboSub final.

“All of the genuine problems from before are more or less gone,” Mori said. “We’re in a place where this is the robot. It’s stable. It does its job. And it didn’t explode.”

“The goal has always been to make the finals,” Trapier added. “Just now we’re in a position where it seems like it’s a lot more feasible considering all of the work we put into SeaWolf 8.”

To prepare for competition, the AquaPack team tests SeaWolf in pools at least 10 feet deep, usually at Carmichael Gymnasium. They also schedule time at a nearby outdoor pool to make sure the AUV’s camera is functioning well in different lighting conditions. Tests can take up to five hours. Working over long periods of time is good practice for the seven-day competition, which involves an orientation day, a qualification day, three days of semi-finals and one day for the final.

…promoting that kind of design cycle is more akin to what you would face in the real world.” – Chris Mori

RoboSub starts with a qualifying task called “Gate.” The AUV has to pass through the gate at any depth. Once it gets through, it relies on computer vision and acoustic signals to navigate an obstacle course of several tasks: following a path, touching a buoy, dropping objects into a bin and removing the cover of a bin, shooting torpedoes through two different-sized holes and surfacing within a floating octagon.

The competition is intense, and often frantic. A minimum of 36 international teams participate each year, and all are vying for practice time in the pool. The days start at 6 a.m. so that students are there in time for the 6:45 a.m. raffle that determines the first round of 30-minute testing timeslots. AquaPack organizes students into shifts to help reduce fatigue and increase the number of students able to participate in the competition.

Preparing for future success

As a student-led 501(c)3 organization, AquaPack has its own budget of about $50,000 funded by dues, corporate sponsors, university programs and grants. The group has 40-50 members cycling in and out throughout the year, with a core group of about 20 people who regularly work on the robot.

Mori and Trapier have been involved since they were undergraduate students at NC State, and they are transitioning out of leadership roles. Both are optimistic about the future of AquaPack, which had a boost in membership in 2023-24, with 80 percent of members showing up to at least one event per week. They are also excited about the new design cycle and having two AUVs available.

“It really is almost a startup atmosphere where you have this one goal,” Mori said. “We have these people with this technical knowledge and experience, and we’re building end-to-end and dealing with the budgeting, dealing with the logistics.”

Most AquaPack members join because they are interested in robotics. But many, especially leaders, learn much more, including entrepreneurship skills, teaching and teamwork.

“I just always thought robots were cool,” Trapier said. “Our club fosters more of a family environment, and so it became more of a case where I really want to make sure this thrives and continues to grow. I just wanted to support the team as much as possible and make sure it does as well as possible.”

- Categories: