The Department of Forest Biomaterials, in partnership with Aalto University, Valmet, and Tapio Measurement Technologies, is excited to announce the successful completion of the initial stages of the BETTER experiment at the “WolfPack Baby” Pilot Plant Paper Machine. The “WolfPack Baby” is an essential part of the Paper Science and Engineering program, providing students with hands-on experience on a small-scale paper machine, which prepares them for successful careers in the industry.

BETTER, short for Beyond Traditional Roll Service, is a research project that aims to enhance paper quality and paper machine runnability by improving how we measure paper online, service the rolls, and monitor their condition. Essentially, the goal is to use data from the paper machine to make better adjustments to the rolls, which are crucial components in paper production. The BETTER project is part of Valmet’s extensive R&D program Beyond Circularity.

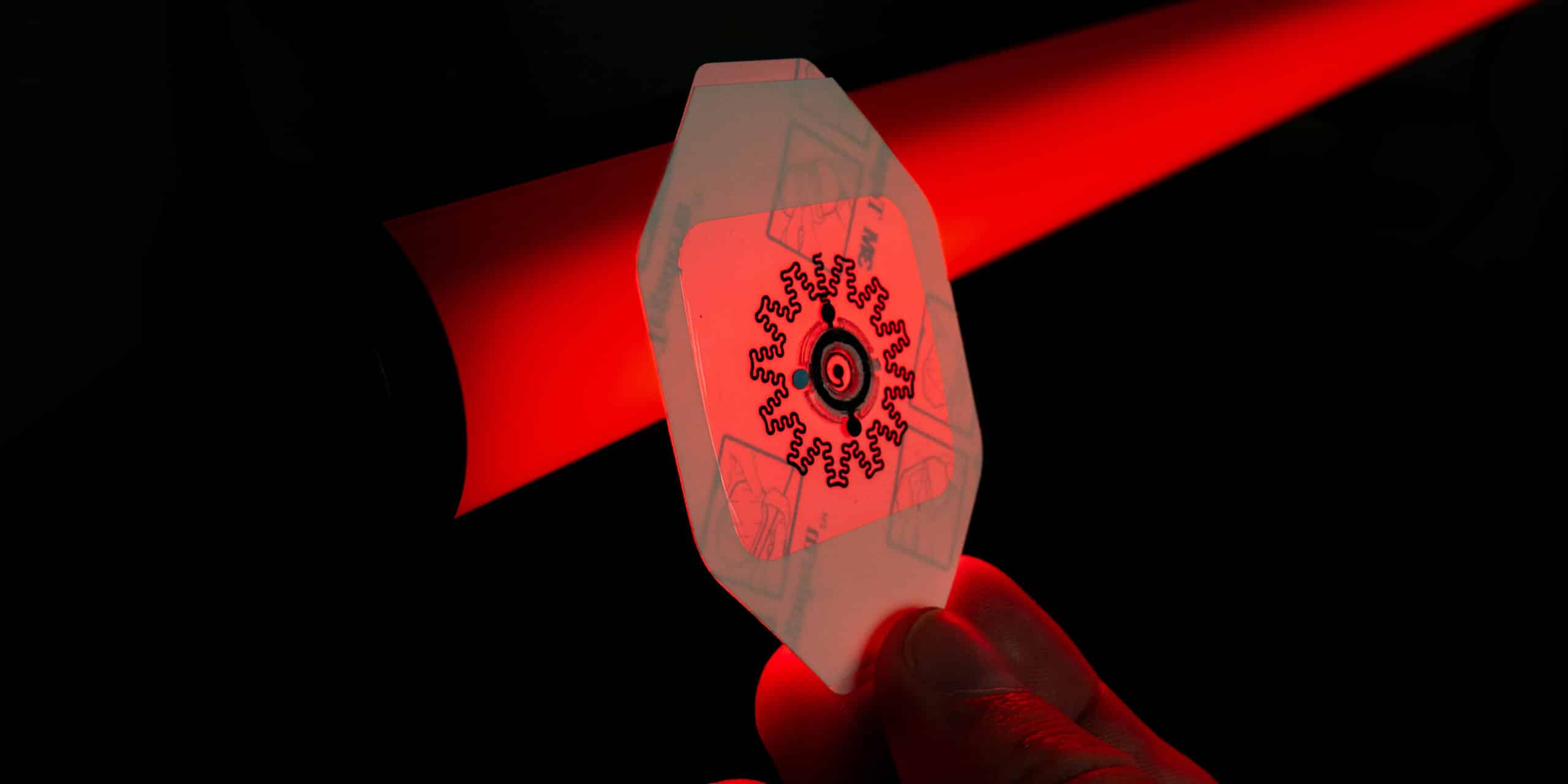

During the experiment, three paper machine rolls were identified that needed refurbishment. Quality variations in the paper were measured online and by Tapio Measurement Technologies in Finland, and these variations were linked to the rolls that required grinding. The rolls were then measured and ground at Valmet’s facility in Aiken, SC. Valmet provided the grinding machines and expertise for this process. After grinding, the rolls were reinstalled in the pilot paper machine. Another run at Wolfpack Baby demonstrated the experiment’s success, as preliminary data analysis showed a decrease in machine direction quality variation due to the improved roll geometries.

The enhanced data analysis of the paper online measurement and the improved roll grinding process makes the paper machine rolls operate more efficiently, improving the quality of the paper. This will eventually result in significant cost savings through better condition monitoring, improved roll maintenance schedules and reduced waste due to unscheduled maintenance breaks and scrapped production. Additionally, the tools and research findings from the BETTER project will enable students and engineers to learn from and apply these advancements in their own work.

A special thank you to the contributors of this project – Raine Viitala, Sampo Haikonen, Thomas Widmaier (Aalto), Tuomas Tiainen (Tapio Measurement Technologies), Jukka Toikkanen, Heikki Kettunen (Valmet), Lokendra Pal, Hasan Jameel, Med Byrd, Ronald Marquez (NC State).

This post was originally published in the Department of Forest Biomaterials.

- Categories: