New equipment will help TPACC researchers test military, fire fighting gear for women who serve

As the number of women holding roles in the armed forces and fire services grows by the year, researchers at the Wilson College of Textiles are touting new technology that will help those critical service members serve more comfortably and safely.

Last summer, NC State’s Textile Protection and Comfort Center (TPACC) received a new manikin designed to test the effectiveness of garments.

As remarkable as its ability to produce heat, sweat and walk is, similar technology has existed for years. In fact, TPACC researchers have had access to so-called “sweating manikins” for decades.

But none have been specifically designed and shaped to test women’s garments. It’s a glaring deficiency considering the growing portion of these critical workforces occupied by women.

“The percentage of females keeps growing year after year in terms of how many are in fire fighting, police work and the military,” says Shawn Deaton, TPACC operations director. “There’s studies looking at the shape of a garment and how it’s made, but then, how does it actually interact with the body and change the performance for females? That’s what we truly need to understand.”

Soon, that will be a reality.

How the new manikin works

The fact that insufficient testing mechanisms exist for the garments worn by women in the military or fire service has seemingly become more problematic by the year.

In 2022, the number of active duty women service members climbed to 17.5% of the active duty force, according to a report from the U.S. Department of Defense. That’s despite overall declines in the number of service members overall.

Similarly, the National Fire Protection Association in 2020 reported an increase in the number and proportion of female firefighters over the previous decade.

Yet, the organization noted, studies show as many as 80% of female firefighters experience problems with improperly fitting personal protective equipment, from gloves to boots, pants and coats.

It’s a problem that can not only fuel discomfort, but also present a serious safety risk in the midst of the dangerous working conditions inherent to the profession.

Deaton’s team hopes to solve precisely those discrepancies with the help of TPACC’s new female-shaped testing manikin.

For example?

“Typically females have a smaller frame, and a ballistic vest would weigh more and be more taxing for them,” Deaton offers. “So, we need to know how that will actually affect a female as opposed to a male.”

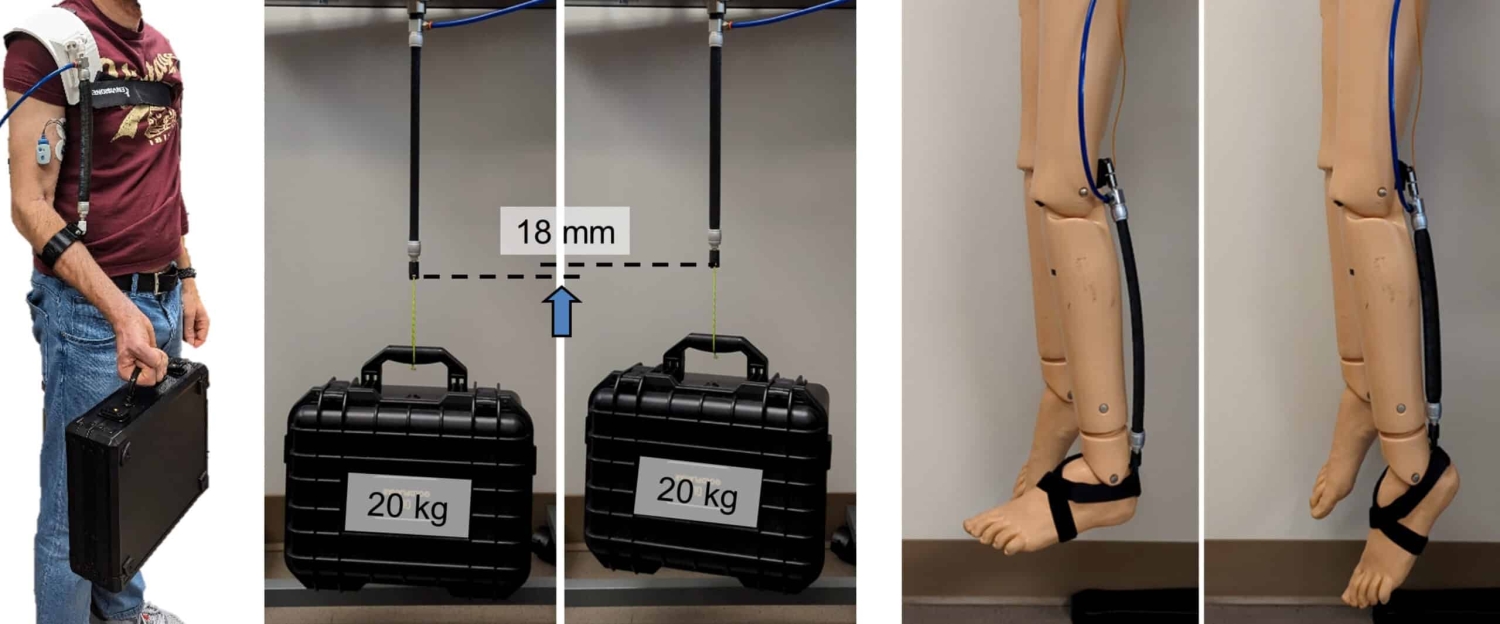

Like the new manikin’s existing male counterparts, the new female sweating manikin has several potential uses.

Certainly, it can help the TPACC team test a garment’s comfort, fit, construction and design.

Importantly, though, it should also allow researchers to investigate how a garment performs in the face of heat or moisture. The opportunity to measure on a more realistically-shaped manikin should help researchers more accurately predict how clothing performs in a real-life working environment…such as fighting a fire.

Fueling innovative research

The manikin has dozens of pores that produce sweat.

Operated inside a climate-controlled chamber in TPACC’s facilities on Centennial Campus, that makeshift “sweat” comes from preheated water supplied via simulated moisture glands controlled by the human user.

A body suit covering the manikin acts as a layer of skin.

Using this equipment, TPACC researchers will test a variety of factors, such as a fabric’s insulation — a critical safety component in the fire service. Or, researchers might test how overheated someone might become while wearing a particularly heavy duty vest or coat.

They can also use the simulated sweat to examine how effective a particular article of clothing is at absorbing moisture … and then at allowing that moisture to evaporate.

The TPACC team has spent the early months getting to know how the new manikin works.

Now, they’re ratcheting up the research, and hoping to get external partners involved.

“I know the military is extremely interested in learning more about how clothing influences physiology for women who serve in these critical positions,” Deaton says. “Our industry partners are also extremely interested. Until now, they’ve had to compare the performance of female-oriented gear using male-shaped manikin.”

In fact, the technology arrived at NC State with the assistance of a Federal Emergency Management Agency (FEMA) grant, awarded to TPACC through an Assistance to Firefighting Grant, which helps fund critically needed resources, including those to equip and train emergency personnel.

It’s the latest significant advancement at the corner of research and industry at TPACC, the only academic center in the U.S. that incorporates capabilities to research, test and evaluate the comfort and protective performance of textile materials, garments and ensemble systems all at one location.

Mushfika Tasnim Mica, a doctoral student in the textile technology management program, is among the researchers applying the new manikin’s capabilities to research.

Her research focuses on developing firefighting gear and ballistic vests that don’t cause service members to become overheated — including women in these critical fields.

“How it impacts them in terms of thermal or heat strain, and other related issues such as range of motion or mobility,” Mica explains. “It’s really about how we can suggest more comfortable configurations for firefighters … that will improve their performance and safety in the workplace.”

This post was originally published in Wilson College of Textiles News.

- Categories: